Fastener Material Selection & Plating Guide

Leave a CommentSelecting the proper fastener material and finish can make or break a project—especially those with intended applications underwater or in harsh environments. With many options available, many professionals struggle to find the best choice for their application. Below, we’ll cover choosing an appropriate fastener material for your project and provide guidelines regarding finish selection.

CHOOSING THE BEST FASTENER MATERIAL FOR YOUR PROJECT

Fasteners can be manufactured from a wide variety of materials, and the available coating and finishing options help users tailor a solution specific to their application. Alloy steels, aluminum, and carbon steel all see frequent use, but manufacturers can also create fasteners from numerous plastics, brass, nylon, and other materials.

MATERIALS AND PROPERTIES LIST

At National Bolt, we offer our clients a choice in materials from the following list:

- Alloy Steels

- Low corrosion resistance

- Often requires additional coating

- High strength

- Often brittle or rigid

- Aluminum

- Light and soft

- Corrosion-resistant

- Beryllium

- Brass

- Corrosion-resistant

- Electrically conductive

- Relatively soft

- Often selected for aesthetic purposes

- Silicone Bronze

- Often utilized in marine environments

- Superior corrosion resistance compared to stainless steel

- Higher-strength than standard bronze

- Carbon Steel

- Magnesium

- Molybdenum

- Monel

- Inconel

- Nickel

- Stainless Steel

- Highly corrosion-resistant

- Often stronger than un-hardened steel, but weaker than hardened steel

- Tin

- Titanium

- Extremely corrosion-resistance

- Superior strength to weight compared to aluminum

- Ideal for high-temperature environments

- Frequently utilized in the aerospace industry

- Various Plastics

- Nylon

- One of the most commonly-used plastics

- Exceptional strength at all grades

- Excellent wear resistance

FASTENER FINISHES OPTIONS

The ideal finish depends heavily on the intended end use of the fastener. Many finishes can help to prevent corrosion or increase strength. The materials used to create and finish fasteners can heavily impact their ideal use; the strength, brittleness, corrosion resistance, and cost of these materials all vary and play into the selection process before fabrication begins.

There are a number of options for finishing custom-manufactured fasteners. Whether the intent is to boost strength, improve corrosion resistance, or achieve another niche goal, there’s likely a coating designed to provide the advantage your application requires. We provide clients with a full range of finishing options, including:

- Black Oxide

- Mildly improved corrosion and abrasion resistance

- Reduces reflective properties

- Complies with military specifications

- Good plating for a decorative appearance (i.e. fasteners used in indoor furniture applications)

- Hot Dip Galvanizing

- Adds corrosion resistance

- Ideal for harsh environments

- Zinc Plating

- Not suitable for extreme environments

- Improved corrosion resistance

- Chrome Plating

- Improved aesthetics

- Improved corrosion resistance

- Hard chrome can be utilized to minimize friction and increase abrasion resistance

WHAT IS GALVANIC CORROSION? HOW CAN IT BE AVOIDED?

Galvanic corrosion takes place when incompatible metals come into electrical contact while submerged in water or salt water. The first metal (the anode) corrodes more quickly while the other (the cathode) corrodes at a slower rate, resulting in half of the component material corroding away.

Careful material selection mitigates the risk of galvanic corrosion. Dissimilar material combinations should be avoided when selecting metal paneling, trim, and fasteners for underwater applications.

FASTENER SOLUTIONS FROM NATIONAL BOLT

National Bolt offers our clients a wide variety of custom non-standard fasteners to suit the needs of any operation. We pride ourselves on quick delivery and also offer emergency same-day services. Our capabilities include:

- Large diameters

- High strength

- Exotic materials

- Prototypes

- Line-Down

For more information about our fasteners and capabilities, please contact us or request a quote.

Left-Handed and Right-Handed Fastener Threads: Uses and Comparison

Leave a CommentFasteners are the nuts, bolts, screws, and other small components that keep machinery and components together in working order. Many fasteners work through the effective use of threads (left-hand thread and right-hand thread), which allow nuts and bolts to screw together effectively.

But how do threads work? The direction in which workers screw and unscrew fasteners has a lot to do with the applications in which they appear. Additionally, many different types of threads exist to optimize different ways to fasten objects. In this blog, we explore a few of the many different varieties of threads as well as their uses.

COMMON USES AND APPLICATIONS OF FASTENER THREADS

Screw threads help with many different applications, such as:

- Fastening: Screw threads appear on traditional fasteners such as nuts, bolts, and screws, and they also help connect threaded pipes, hoses, caps, and fixtures

- Gear reduction: Screw threads help with gear reduction by using worm drives

- Linear object movement: Fastener threads can be used to convert rotary motion to linear motion

UNDERSTANDING RIGHT-HANDED VS. LEFT-HANDED THREADS

THREAD TERMINOLOGY AND DIFFERENT TYPES

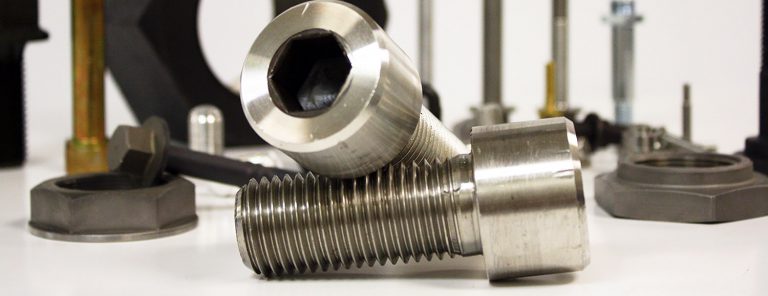

Threads are continuous helical ridges on cylindrical fasteners. For parts such as screws, the ridges will be on the exterior, and parts like nuts have ridges inside of their cylindrical bodies.

There are a number of common terms to describe different aspects of threads, which we define below:

- External threads: Threads that wind around the exterior of a fastener’s shaft

- Internal thread: Threads that run along the inside of a fastener

- Axis: Longitudinal lines used to measure the length of the fastener

- Pitch: The distance between a point on one thread to a point on another thread

- Major diameter: The largest internal or external thread diameter

- Minor diameter: The smallest internal or external thread diameter

FASTENER THREADS: WHAT IS A SCREW THREAD?

Screw threads are sloped helices that spiral down the cylindrical surface of parts like screws and bolts. They’re responsible for converting energy between rotational and linear movement and force. Fasteners with compatible threads can provide tight seals for a wide variety of equipment.

SCREW HANDEDNESS: LEFT-HAND THREAD AND RIGHT-HAND THREAD

Screw handedness refers to the direction that a screw’s thread wraps around its shaft. Right-handed threads run clockwise, and left-handed threads run counterclockwise. The origin of a thread’s handedness is rooted in human physiology: Screws with different handedness are ergonomic for people depending on their dominant hands.

Most screws today use right-handed threads, and it’s rare to find a left-handed screw used in any application that doesn’t specifically call for it. However, there are some applications that specifically call for the use of left-handed fasteners.

USES AND APPLICATIONS OF LEFT-HANDED THREADS

Left-handed threads are also known as reverse threads. These threads are used in specialized applications in which the application of pressure would force a right-handed screw or bolt to come loose.

Some applications that benefit from the use of left-handed fasteners include:

- Automotive: Some tires’ bolts are reverse threaded to keep torque from loosening them

- Heating and plumbing: Pipes are often fitted with both right- and left-handed threads to provide an extra layer of defense from leakage

- Safety: Gas-supply valves use left-handed threads to differentiate them from the valves that control oxygen

QUALITY FASTENING SOLUTIONS BY NATIONAL BOLT

National Bolt builds custom nonstandard fasteners, large-diameter products, and more, and we pride ourselves on our quick turnaround and delivery times.

If you would like to learn more about our custom fastening solutions, don’t hesitate to reach out to us or request a quote today!